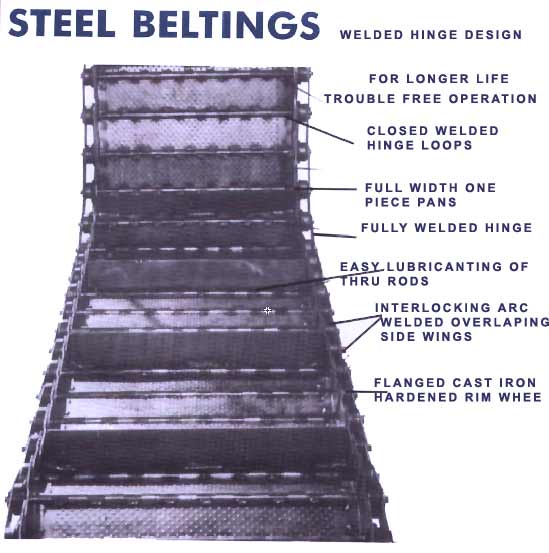

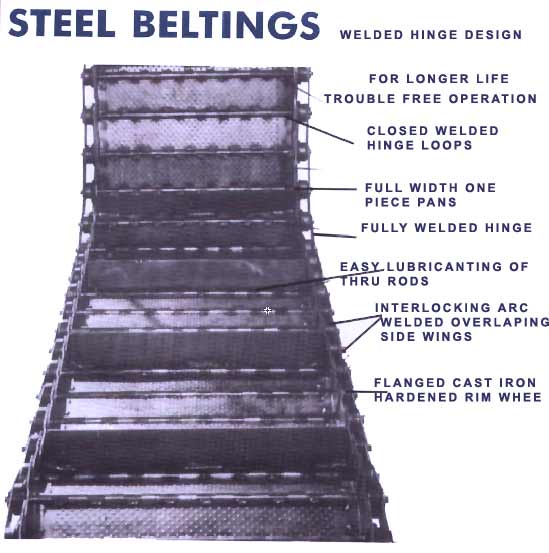

STEEL BELTING CHAINS

|

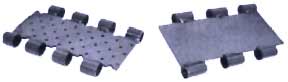

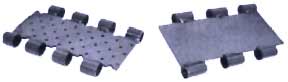

PAN AVAILABEL:

- Dimpled(as shown)

- Perforated Plain

|

|

OPTIONAL WHEEL

|

FORGED STEEL HEAT TREATED |

|

POWDERED STEEL HEAT TREATED |

METHOD OF PAN CONSTRUCTION

| Continuous full width,one-piece parts substantally strengthens the belt against dections from shocks pressure in teh center and reinforce the rods against bending. |

Other methods have the pans in segments(not one piece)and have no latteral support.These inferior methods can leave pans distored and separated by concentrated loads and shocks at the juncture of the segments. |

|

|

SECTIONTHRU PAN LOOPS

|

|

| TOP SIDE |

BOTTOM SIDE |

LUBRICATIONS

|

|

Lubricant of the thru rods with the"Welded Hinge" using no tube is accomplished through the opening between the hinge loops.

HINGE LOPS WITH NO TUBE.....PIN LUBRICANTION MADE EASY BETWEEN THE LOOPS |

HINGE LOOPS WITH TUBE AND PIN .PIN LUBRICANTION BLOCKED BY TUBE |

BASIC "WELDED HINGE" BELTS SPECIFICATIONS

| NORMAL BELTWIDTH |

"6" PITCH CHAIN |

|

|

|

| CHAIN CTRS B |

D.A. WIDTH C |

INSIDE WINGS D |

CHAIN CTRS. B |

D.A.WIDTH C |

INSIDE WINGS D |

| 12 |

14 5/18 |

17 3/8 |

11 3/16 |

15 9/16 |

20 3/8 |

11 3/76 |

| 18 |

20 5/16 |

23 3/8 |

17 3/16 |

21 9/19 |

26 3/8 |

17 3/16 |

| 24 |

26 5/16 |

28 3/8 |

23 3/16 |

27 9/16 |

323/8 |

23 3/16 |

| 30 |

32 5/16 |

35 3/8 |

28 3/16 |

33 9/16 |

38 3/8 |

29 3/16 |

| 36 |

38 5/16 |

41 3/8 |

35 3/16 |

39 9/16 |

44 3/8 |

35 3/16 |

| 42 |

44 5/18 |

47 3/8 |

41 3/16 |

45 9/16 |

50 3/8 |

41 3/16 |

| 48 |

50 5/16 |

53 3/8 |

47 3/16 |

51 9/16 |

56 3/8 |

47 3/16 |

| 54 |

56 5/16 |

59 3/8 |

53 3/16 |

57 9/16 |

62 3/8 |

53 3/16 |

| 60 |

62 5/16 |

65 3/8 |

59 3/16 |

83 9/16 |

68 3/8 |

58 3/16 |

BASIC CHAIN SPECIFICATION

| ROLLER |

| AVG.PITCH |

TYPE |

DIA G |

WIDTH H |

TREAD T |

DIA. D |

END STYLE |

THK L |

WIDTH M |

SPACE E |

D.A.WIDTH |

ALLOWABLE BELT PULL |

| 6 |

1 |

21/2 |

13/16 |

11/18 |

|

3 |

1/4 |

2 |

11/4 |

25/26 |

5,780 |

| 6 |

2 |

3 |

11/2 |

13/18 |

3/4 |

3 |

1/4 |

2 |

16/16 |

25/8 |

7,200 |

| 6 |

3 |

3 |

11/2 |

13/16 |

3/4 |

50 |

1/4 |

2 |

15/16 |

25/8 |

7,200 |

| 9 |

2 |

3 |

11/2 |

13/16 |

3/4 |

3 |

1/4 |

2 |

19/16 |

25/8 |

7,200 |

| 9 |

3 |

3 |

11/2 |

13/16 |

3/4 |

56 |

1/4 |

2 |

19/16 |

25/8 |

7,200 |

| 9 |

3 |

4 |

115/15 |

17/16 |

3/4 |

56 |

3/8 |

2210 |

2 |

35/18 |

10,400 |

| 9 |

3 |

4 |

115/18 |

17/18 |

1 |

56 |

3/8 |

|

2 |

35/18 |

13,600 |

<<BACK

| wiperdrive© copyright. 2002 |

|