|

|

|

|

|

|

Wiperdrive are prime Group of engineering industries, functioning more than two decades, catering the needs of almost major industries with their PRODUCT RANGE : FREEWHEEL (ONE WAY) CLUTCHES, KEYLESS TRANSMISSION ELEMENTS, TENSIONER NUTS, SPEED VARIATIORS, CAM FOLLOWERS (TRACK ROLL) ETC; Freewheel-oneway-Clutches (Unidirectional Couplings) leads to reduction in cost as compared with separately controlled other equipments/attachments.No driving contact between inner and outer ring in one direction of rotations and there is driving contact between inner and outer ring in the direction of rotation which transmit torque.Three type of freewheels,viz.1.Sprag1.1.standard,1.2 Indexing ,1.3 Centrifugal lift off 2.Roller,3.Cam-Roller Combined,used as Overrunning Coupling,Indexing(feeding)& Backstopping clutch. Keyless Transmission Elements :Shrink fit connection of special variety. Versatile, high fatigue strength, even under alternating torsional stresses. Shaft/hub has no keyway, minimizing notch effect. Most suitable for shaft hub connection. Easy mounting and removal, wear free, perfect alignment, easily adjustable, economical.. shaft mounted gearing, gear wheels, chain sprockets, lever, cams, break drum and countless other application. Elements are available in modesl N7012, N7012.1, N7013.0, N7013.1, N7014, N7015, N7016, N8006, N250, N500 and Shrink Disc N4071, N4091 & split type NS4051, NS4071, NS4091. Tensioner Nuts : can be instead of standard hexagonal nuts on stud OR bolt for general mechanical connections-heavy Or medium duty. Bolt tension-clamping load-by tightening multi clamping screws with standard tool-torque wrench only. Variable Speed Units : are compact in construction much useful and advantageous where infinitely variable speed drive is required. Speed variation by hand wheel / by other mechanism in lace of hand wheel / by other mechanism in place of hand wheel. Gives out put ratio 6:1 Input power 0.25 to 2.2K.W. Out put speed 1.5 to 1700 RPM. Cam Followers / Stud Type Track Rollers / Track Rollers : are with standard as well as eccentric stud, cage guided ready to fit. These are equiv. To KR/CR/CF & are used for heavy loads and medium speeds. All Wiperdrive PRODUCTS have versatile functions and are extensively and economically used in all most all industries and have gripped the manufacturing industries as a whole |

|

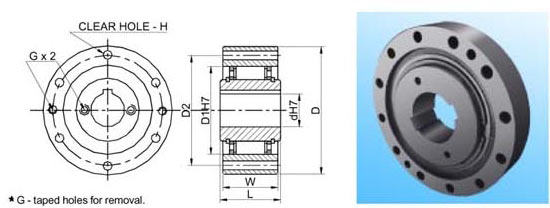

These units do not have bearings so to ensure fault-less operations inner & outer ring have to be aligned properly concentric and square with reference to the shaft axis.For this,the inner dia"D1" of outer ring of Hold Back Device is to be firmly fitted on centering spigot of stationery part of machine /gearbox.It is advisable that inner dia"d1"should not be kept dry but be cleaned & slightly oiled.Spigot is to be machine perfectly square with reference to shaft axis and dia "D1" within "h7" limit.The height of spigot is to be keept such ,as that the centering spigot must touch NOWHERE to th ecage portion. |

|

|

To insert inner ring with sprag cage assembly,keep sprag in disengaged position by means of thin flexible wire ring OR any stretchable ring,slightly turn in freewheeling directions during entering in outer ring .While 1/3 portions of all sprags enter in the puter ring ,remove wire OR stretchable ring and insert total sprag cage assembly. Lubrication: Normally ,these units are running in disengaged position,lubrication is required to protect against corrosionsonly and most probably this is covered by oil immersed lubrications,in gear boxes & other machines.Where applications differ,(fig.3) we suggest to fill 1/3 portion of unit by low viscosity hydraulic oil. Before putting into operations proper lubrication should be provided.Hold Back Device-a versatile Products -equiv .to FXM,RS/BI,CLS seriesNormally ,these units are used as overrunning clutches,where the shaft overruns at high speed.These units are having Individually spring loaded centrifugally lift off sprags,housed in a cage by means of pins connected with rotating inner ring having driving contact with outerring .When the lift off speed is reached the sprags automatically disengage completely from the contact surface of the outer ring and rotate contact free ,hence sprags are wear free & having longlife. |

|

| dH7 |

D

|

l | W | D1 | D2 | torque Nm | Lift Speed (rpm) | H | |

| Nos | Dia | ||||||||

20 25 30 35 40 45 50 60 70 80 90 95 100 120 140 185 190 220 |

90 95 100 110 125 130 150 175 190 210 230 245 270 290 310 400 420 260

|

35 35 35 35 35 35 40 60 60 70 80 80 90 90 90 105 105 105 |

35 35 35 35 35 35 40 50 50 60 70 70 80 80 80 80 80 80

|

66 70 75 80 90 95 110 125 140 160 180 180 210 210 240 310 330 360 |

78 82 87 96 108 112 132 155 165 185 206 218 240 258 278 360 380 410 |

120 180 250 300 450 500 800 1200 2000 3000 3300 4200 5800 9000 12200 16500 20000 27000 |

800 750 700 625 580 550 500 450 450 430 400 400 350 350 300 290 275 250 |

6 6 6 8 8 8 8 8 12 12 12 12 12 12 12 12 12 16 |

6.8 6.8 6.8 6.8 9 9 9 11 11 11 13 13 17 17 17 21 21 21 |

| Only Fitting/External dimensions can be made according to other equivalents,if required . | ||

| Other sizes on request | Design subject to modifications | All Dimensions are in m.m. |

| wiperdrive© copyright. 2002 |